01 . Mold laser cleaning by Tinho Intelligent Handheld Laser Cleaning Machine

The laser cleaning method is highly flexible in use, and the dead corners or parts of the mold that are not easy to clean are easy to clean. The technology of laser cleaning tire molds has been widely adopted in the tire industry in Europe and the United States, and the benefits obtained in saving standby time, avoiding mold damage, working safety, and saving raw materials are quickly recovered. According to the cleaning test conducted by the laser cleaning equipment on the tire company’s production line, it only takes 2 hours to clean a set of large truck tire molds online; compared with conventional cleaning methods, the economic benefits are obvious. The anti-sticking elastic film layer on the food industry mold needs to be replaced regularly to ensure hygiene. Laser cleaning without chemical reagents is also particularly suitable for this application.

02. Weapons and equipment cleaning by Tinho Intelligent Handheld Laser Cleaner

The laser cleaning system can remove rust and pollutants efficiently and quickly, and can select the removal part to realize the automation of cleaning. Not only the cleanliness is higher than the chemical cleaning process, but also almost no damage to the surface of the object. By setting different parameters, a dense oxide protective film or molten metal layer can also be formed on the surface of the metal object to improve the surface strength and corrosion resistance. The waste material removed by the laser basically does not pollute the environment, and it can be operated remotely, effectively reducing the health damage to the operator.

03. Removal of old aircraft paint by Tinho Intelligent Laser Cleaning System

European laser cleaning systems have been widely used in the aviation industry. The original old paint needs to be completely removed before regular painting on the surface of the aircraft. The traditional mechanical paint removal method can easily cause damage to the metal surface of the aircraft and bring hidden dangers to safe flight. Using multiple laser cleaning systems, the paint on the surface of an A320 Airbus can be completely removed within two days without damaging the metal surface.

04. Building exterior wall cleaning by Tinho Laser Cleaner

The laser cleaning system provides a solution to the cleaning of the exterior walls of buildings. It can effectively clean various contaminants on various stones, metals, and glass, and the efficiency is many times higher than that of conventional cleaning. It can also remove black spots and stains on various stones of buildings. The cleaning test of the laser cleaning system on the buildings and stone steles in Songshan Shaolin Temple shows that the use of laser cleaning has a very good effect on protecting the appearance of ancient buildings and restoring the appearance.

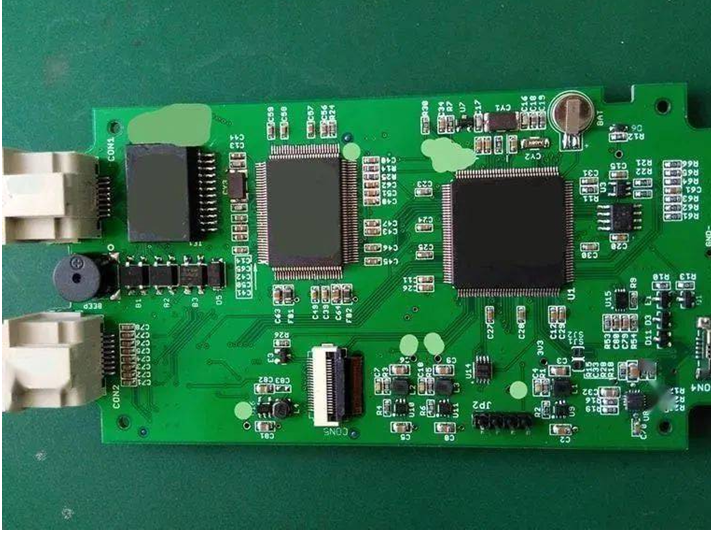

05. Cleaning in the electronics industry by Tinho Hand Laser Cleaning System

The electronics industry uses lasers to remove oxides. Before the circuit board is soldered, the component pins must be thoroughly deoxidized to ensure the best electrical contact, and the pins must not be damaged while decontamination. Laser cleaning can meet the requirements of use, and the efficiency is very high, a stitch only needs to be irradiated with the laser once.

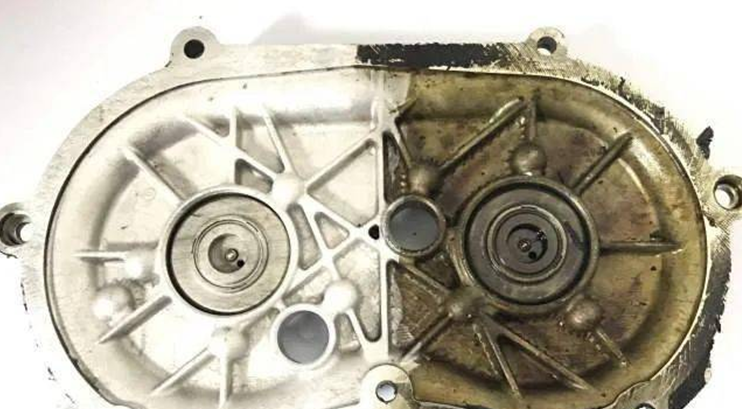

06. Precise deesterification cleaning in the precision machinery industry

The precision machinery industry often needs to remove the esters and mineral oils used for lubrication and corrosion resistance on the parts, and chemical cleaning often still has residues. Laser deesterification can completely remove esters and mineral oil without damaging the surface of the part. The material is thoroughly de-esterified for the cleaning of mechanical parts in the aerospace industry. Laser cleaning can also be used to remove oil and ester in the processing of mechanical parts.

07. Pipeline cleaning in nuclear power plant reactor

The laser cleaning system is also used in the cleaning of pipelines in nuclear power plant reactors. It uses optical fibers to introduce high-power laser beams into the reactor to directly remove radioactive dust, and the cleaned materials are easy to clean. And because it is operated remotely, the safety of the staff can be ensured.

Laser cleaning plays an important role in many fields, and is used in automobile manufacturing, semiconductor wafer cleaning, precision parts processing and manufacturing, military equipment cleaning, building exterior wall cleaning, cultural relics protection, circuit board cleaning, precision parts processing and manufacturing, liquid crystal displays Cleaning, chewing gum residue removal and other areas can play an important role.

Shanghai Tinho Intelligent Equipment Co., Ltd. is located in Shanghai, As a high-tech enterprise dedicated to R& D, manufacture and sales of inkjet coding & laser equipment, holds more than 20 patents on technology and software to guarantee machine with high quality & high performance, till to now the Tinho full series products included Small character inkjet printer, Laser Marking Machine, Thermal Inkjet Printer, Laser cleaning machine, Laser welding machine already sold well to different country with a good evaluation,if any further assistance or inquiry, welcome to contact us at any time.

Tinho Intelligent

TEL: +86 137 6190 3268 (Whatsapp)

Email: sales@tinhointelligent.com

Web.: www.tinhointelligent.com