The laser cutting machine is an important tool in the cutting field and is known as the fastest “knife”. The principle is to irradiate the surface of the material with a high-density and high-energy laser beam to vaporize and remove part of the material to form a cut. According to wavelength characteristics, laser cutting machines are divided into CO2 laser cutting machines, fiber laser cutting machines, green laser cutting machines and ultraviolet laser cutting machines in industrial applications.

Laser cutting processing is to replace the traditional mechanical knife with an invisible beam. It has the characteristics of high precision, fast cutting, not limited to cutting patterns, automatic typesetting, saving materials, smooth cuts, and low processing costs. It will be gradually improved or replaced. Traditional metal cutting process equipment.

So, what are the differences between fiber laser cutting machine and ultraviolet laser cutting machine?

Analysis of the difference between fiber laser cutting machine and ultraviolet laser cutting machine:

1. The difference of processing materials:

The application range of laser is very wide. Whether it is fiber laser or ultraviolet laser, it can be applied to metal and non-metal materials. In particular, the application range of ultraviolet laser is more extensive, covering almost all fields from metal to non-metal.

According to the characteristics of the material being processed, the absorption of the laser waveband is different, so the laser cutting machine selected is different; according to the quality requirements of the processing, the higher the requirements on the beam quality and thermal influence of the laser, the laser cutting machine selected will also be different ; According to the thickness requirements of the processed material, the threshold range that the laser can achieve within the wavelength range is different, and the selected laser cutting machine is also different.

In the processing of metal materials, the fiber laser cutting machine and the ultraviolet laser cutting machine have a certain degree of homogeneity, and both can process ultra-thin metal materials below 0.2mm, such as copper, nickel, and titanium alloys. The difference is that the fiber laser cutting machine processes ultra-thin metal through galvanometer scanning, the edges will be severely carbonized, the edges will be deformed due to thermal influence, and the edges of different materials may even have burrs. The efficiency of ultra-thin metal processing by ultraviolet laser cutting machine is lower than that of optical fiber, but the processing effect is good, the edge is free of burrs, the degree of carbonization is low, and the edge will not be deformed due to heat. This difference lies in the processing principle of the fiber laser cutting machine and the ultraviolet laser cutting machine. The fiber laser cutting machine is vaporized cutting, and the ultraviolet laser cutting machine is processed by breaking the molecular bond mode of the material, and the thermal effect is smaller.

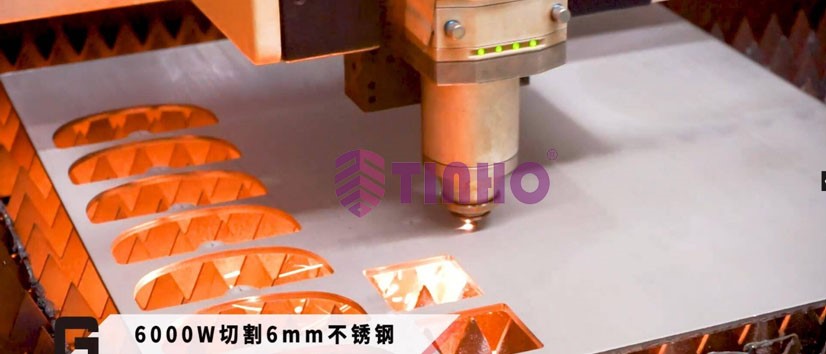

Fiber laser cutting machine has higher power and greater thermal influence. It is often used for cutting thicker metal materials, such as stainless steel cutting, carbon steel cutting, etc. It uses collimated focusing head cutting, which has high processing efficiency. The power of the UV laser cutting machine cannot achieve higher power at this stage. It can only be used for the cutting of thin non-metallic materials and ultra-thin metal materials. Peel cutting.

2. The difference in processing methods:

The fiber laser cutting machine uses an infrared fiber laser with a wavelength of 1064nm, which is processed by collimation and galvanometer.

The ultraviolet laser cutting machine uses a 355nm wavelength UV ultraviolet laser, and it can also use collimated focusing head and galvanometer scanning processing methods.

The common collimating focusing head is the one-time forming method of laser cutting metal materials that we have seen, and the scanning of the galvanometer is like the processing method of laser marking, and the material is peeled off layer by layer to form a cut. Obviously, the efficiency of the collimating focusing head processing method is higher, but the power requirements are also higher. The power of the common fiber laser cutting machine in the market can be more than 20KW, while the power of the ultraviolet laser cutting machine can only be hundreds of watts in foreign countries, while the power of the current domestic market can only be tens of watts.

Shanghai Tinho Intelligent Equipment Co., Ltd. is located in Shanghai, As a high-tech enterprise dedicated to R& D, manufacture and sales of inkjet coding & laser equipment, holds more than 20 patents on technology and software to guarantee machine with high quality & high performance, till to now the Tinho full series products included Small character inkjet printer, Laser Marking Machine, Thermal Inkjet Printer, Laser cleaning machine, Laser welding machine already sold well to different country with a good evaluation,if any further assistance or inquiry, welcome to contact us at any time.

Tinho Intelligent

TEL: +86 137 6190 3268 (Whatsapp)

Email: sales@tinhointelligent.com

Web.: www.tinhointelligent.com