With the improvement of the social and economic level, consumers’ demands are getting higher and higher, and choices are increasing. The market is increasingly competitive. In addition to the high quality of the daily chemical products, people have also presented new challenges to the packaging design itself. It is necessary to protect these products through packaging, and to allow consumers to identify product information through clear labels on the packaging, so as to achieve a healthy and safe entry of the product into the market. Such as shower gel, laundry detergent, cosmetics, and other cleaning products commonly used in life. The application of laser printers in the daily chemical industry is becoming more and more important and more and more important. In this environment, the daily chemical industry urgently needs a coding technology that is conducive to product control and safety and environmental protection, to prevent bad merchants from mixing bad products into the market and endangering people’s health. Therefore, the use of green environmental protection, anti-shedding permanent marking method – laser marking logo, has become a new technology in the new brand of the daily chemical industry brand.

The ability to achieve optimal laser marking depends entirely on the selection process of the laser parameters. With a clear understanding of the materials, applications and required markings, the laser marking system can print high quality markings on a variety of materials. Different combinations of specific wavelengths, printheads, and selected lenses produce different marking effects on a given material. Through the diversified combination of laser head, galvanometer and wavelength, it can meet the application requirements of products in the daily chemical industry.

The CO2 laser coder is particularly suitable for laser marking on cardboard for an attractive marking effect. For the best readable contrast, it is recommended to use darker cardboard or dark marking areas. 1. Coated cardboard 2. Uncoated corrugated cardboard 3. Coated (PE) coated cardboard (usually used for pharmaceutical packaging in Asia – this board requires a different wavelength than other cardboard) 4. Cardboard with laser-sensitive coating .

Similar to cardboard, the CO2 laser logo of the label provides high quality, high contrast marking. There are two main types of labels: paper labels and metal labels. Other labels suitable for use with CO2 laser coder are laminated labels and laser-sensitive coated labels. Paper labels are best suited for CO2 laser coders for fast, high-quality marking.

The CO2 laser marking system also typically prints serial numbers, internal tracking numbers and traceability information on glass (white or stained glass). Two-dimensional coding is less common, but can be achieved by using a suitable spot size. It is recommended to use a smaller spot size to identify the glass for a smooth marking surface finish. The use of larger spot sizes can result in large micro-cracks that make the touch feel rough.

The laser marking technology used in laser printers is developing in the direction of higher precision and clarity, and meets the need to engrave large amounts of data on smaller parts and plastic parts, which can bring beauty to the daily chemical industry. Fine, clear packaging marks. Moreover, the daily laser printer is not like ink jetting, and will not fade due to external environmental influences such as touch, acid and alkali gas, high temperature and low temperature, air humidity, etc., and it will not easily disappear after long-term use, and the mark is permanent.

More importantly, the date traditionally used by inkjet printers is easily erased or tampered with. It is not difficult for lawless elements to resell after the date of production on the food packaging. With the daily laser printer, it is not easy to change the mark. And the use of daily necessities laser inkjet printers through the “two-dimensional code traceability system” to achieve full traceability, can strengthen the supervision of distribution and agents around the country, effectively prevent the market from stocking.

Customized daily laser application solutions:

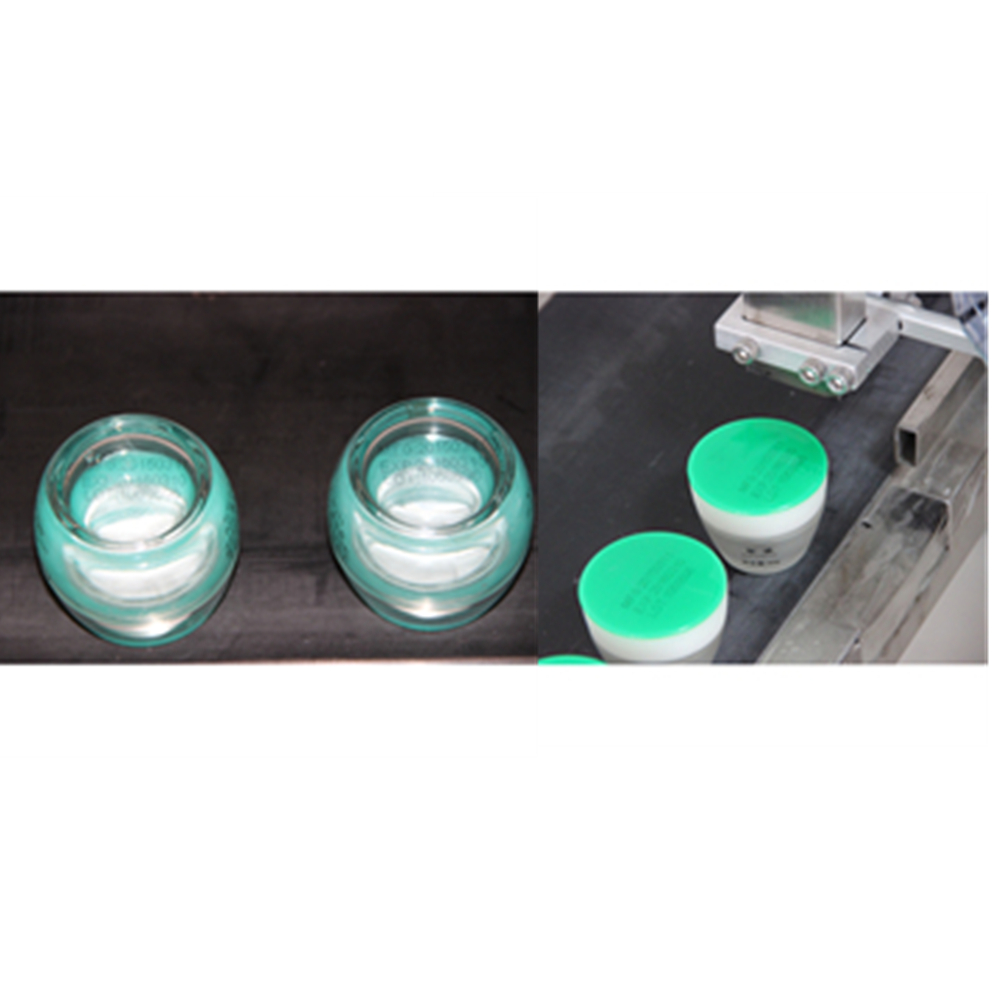

In order to achieve the best marking effect, Henan Tianhe Intelligent Equipment Co., Ltd. designs a professional laser application solution for daily chemical industry to meet the needs of different products (including skin care products, toiletries, cleaning products, etc.). Different process (including production date, barcode, QR code, monitor code, etc.) coding requirements. In addition, Henan Tianhe Intelligent Equipment Co., Ltd. also integrates general materials for daily chemical products, providing you with the following product selection options for reference only.

1. Daily chemical products are mostly packaged in plastic materials. The outer packagings are mostly made of paper packaging boxes. For such products, TINHO-THU series ultraviolet laser coding equipment is best used for laser coding, especially for thinner materials and colors. Lighter pigmented bags.

2. For dark paper packaging boxes, TINHO-THC series CO2 laser coding equipment can meet the requirements of fast coding.

3. For the metal bottle cap or the dark plastic bottle body code, the TINHO-THF series fiber laser coding equipment can be used, and the coded characters are clear and not easy to wear.

TINHO is the brand of Henan Tianhe Intelligent Equipment Co., Ltd. As a manufacturer, TINHO has many years of experience in China and is a wholesaler and retailer of different types of laser printing solutions, portable marking solutions.

Key words: fiber laser printer; fiber laser marking machine; CO2 laser printer; ultraviolet laser printer

Contact:Ray Zhao

Mobile: + 86 159 688 54385

Email: sales@tinhointelligent.com Web: https://www.tinhointelligent.com