Compared with large-scale laser welding equipment, hand-held laser welding machine is relatively portable. Tinho Intelligent Laser will share with you today a hand-held laser welding machine. Although it is smaller than large-scale laser equipment, it is also in the process of laser welding. An indispensable member!

The handheld laser welding machine is a portable device that can be operated in a portable way. It is also a precision welding device, but it can be flexibly adapted to various environmental applications in the application. It is a supplementary operation and packaging management for some production. It is suitable for various applications. It can be easily applied in different types of environments, and has the characteristics of higher professional standards and reliability. The professional production goal of the handheld laser welding machine has the advantages of high standards and specialization in the industry. At the same time, it is also a good design to realize the function and practicality in the process of ensuring the welding accuracy.

1. What are the advantages of a handheld laser welding machine?

In the practice of welding production of various types and scales, having a practical operation basis guaranteed by professional functions will be of special significance for improving the goals of practical application and ensuring the practical advantages of professional high standards. Especially fundamentally speaking, the handheld laser welding machine has a portable design, and it has a higher professional standard for the application of production practice. The features of practical function and flexible operation are particularly important.

Hand-held laser cutting machine is quick to get started. Laser welding technology is a technology that uses laser beam as energy to make it impinge on the welding joint to achieve the purpose of welding. It is a new type of welding method with good welding performance and small deformation. , It is widely used for processing and welding on a variety of metals.

2. Which industries can the handheld laser welding machine be applied to?

Kitchenware is used every day in life, such as stainless steel pots and pans. But have you ever wondered how it is made? The kitchen utensils are made of a variety of raw materials, some are made of ceramics, some are plastic, and some are metal stainless steel. Today we are talking about tableware made of metal and stainless steel. We know that one of the processes in the production of kitchenware is welding.

Hand-held laser welding uses high-energy laser pulses to locally heat the material in a small area. The energy of the laser radiation diffuses into the material through heat conduction, and the material is melted to form a specific molten pool.

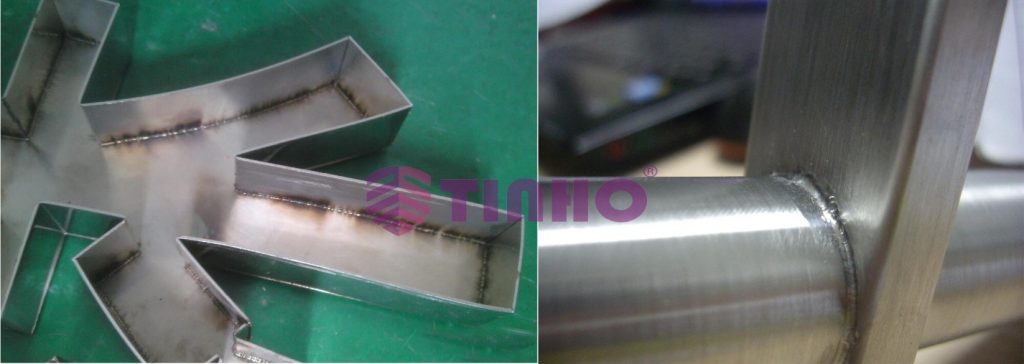

Hand-held laser welding machine in order to be able to make stainless steel kitchenware exquisite and beautiful. If you want to meet the aesthetic and individual needs of current customers for kitchenware, it is difficult for traditional welding methods to fulfill the ideal role.

The hand-held laser welding machine for kitchen utensils saves about 80%~90% of electric energy. Compared with arc welding, the processing cost can be reduced by about 30%. It can weld dissimilar steels and dissimilar metals, and complete mechanization and automation in a simple manner. And the use of hand-held laser welding heat input is extremely low, the amount of deformation after welding is very small, and a very beautiful welding surface can be obtained, and there are few subsequent welding treatments. The hand-held stainless steel laser welding machine can greatly reduce or eliminate the huge polishing and The labor cost of the leveling process.

Sanitary ware, food packaging, glasses, clocks, auto parts, electronic hardware are used in fields that require high depth, smoothness, and fineness, and are suitable for welding between stainless steel, carbon steel, copper, aluminum, and other metal materials.

Laser welding uses high-energy laser pulses to locally heat a material in a small area. The energy of laser radiation diffuses into the material through heat conduction, and the material is melted to form a specific molten pool. In the current laser welding machine market, many laser welding equipment manufacturers are producing laser welding machines. Judging the quality of a laser welding machine is mainly measured from four aspects: the strength of the laser welding machine manufacturer. Only a strong manufacturer can guarantee the quality of the laser equipment, the long-term service and the performance of the laser welding machine. A laser welding machine with good performance, a laser welding machine with good performance not only brings time cost to the business, including material cost, yield rate and so on. The stability of the laser equipment. The stability of the laser welding machine can ensure the normal operation of the equipment.

Hand-held laser welding machines also have quite a few advantages. They play an irreplaceable position of large-scale laser equipment in many processing industries. If you have any doubts about laser equipment, you can pay attention to Shanghai Tinho Intelligent Industry and learn more!

Shanghai Tinho Intelligent Equipment Co., Ltd. is located in Shanghai, As a high-tech enterprise dedicated to R& D, manufacture and sales of inkjet coding & laser equipment, holds more than 20 patents on technology and software to guarantee machine with high quality & high performance, till to now the Tinho full series products included Small character inkjet printer, Laser Marking Machine, Thermal Inkjet Printer, Laser cleaning machine, Laser welding machine already sold well to different country with a good evaluation,if any further assistance or inquiry, welcome to contact us at any time.

Contact Us:

Tinho Intelligent

TEL: +86 137 6190 3268 (Whatsapp)

Email: sales@tinhointelligent.com

Web.: www.tinhointelligent.com